· Application: PVC Sill panel

· Plastic Processed: UPVC K66-K68

· Screw Design: conical twin screw

· Automatic Grade: Fully Automatic

· Place of Origin: Jiangsu, China (Mainland)

· Brand Name: SANSU-PVC sill panel extrusion line

· Voltage: 415V/50HZ, 380V/50HZ, 440V/60HZ, 220V/60HZ

· Power(W): 11-110KW

· Dimension(L*W*H): 20mx2.5mx2.2m

· Weight: 8-20T

· Certification: ISO CE SGS

· After-sales Service Provided: Engineers available to service machinery overseas

· output: 80kg-450kg/h

· using: pvc sill panel

· Screw: Bimetallic screw

· electrical cabinet: Mitsubishi PLC

· Machine motor: SIMO

· Inverter: ABB Frequency Controller

Product Description

Main Model of PVC Sill Panel extrusion line :

|

Model |

65/132 |

80/156 |

92/188 |

|

Applicable product width |

<300mm |

< 600mm |

<900mm |

|

Extruder |

SJSZ65/132 |

SJSZ80/156 |

SJSZ92/188 |

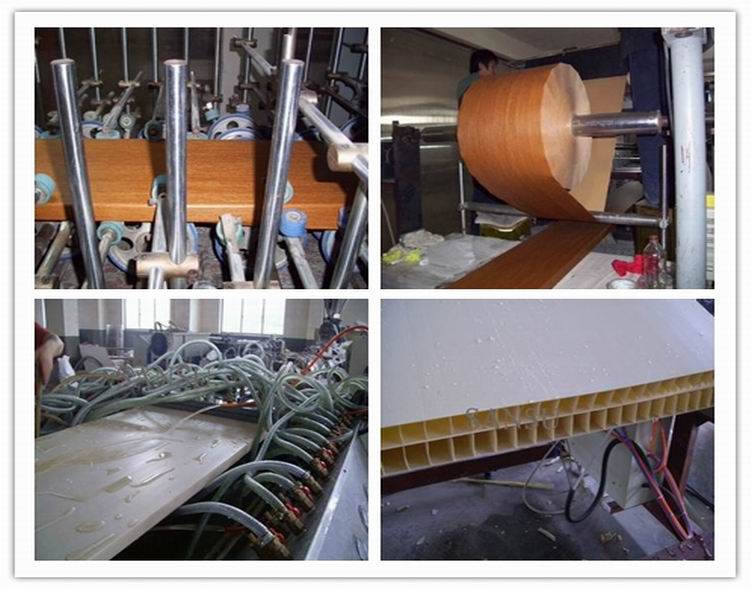

Components of PVC Sill panel extrusion machine:

a. Conical twin screw extruder:

Using the high efficient conical twin screws, specially designed for PVC power to ensure uniformed plasticization, high extrusion. Stable temperature controlling system can guarantee high quality sill panel extrusion.

b. Extrusion Mould:

Spiral type die head will ensure high speed extrusion and avoid the thermal decomposition of amorphous plastics and get high quality PVC sill panel. There is heating control system inside of the mould, high efficient, easy to extrude. Bronze calibrators can make the PVC panel fast calibrated and cooled.

c. Spraying and cooling table:

Rapid vacuum calibrating system allows the hot extruded PVC panel to be cooled in a very short time and obtain the final size. Automatic temperature control system, pressure regulator, and vacuum control valve greatly enhance the sizing and cooling performance as well as the production speed.

d. Haul off machine:

Adopts caterpillar type suitable for different sizes of pipes. Haul off caterpillar blocks are made of abrasion resistant rubber material, which can make a high and stable hauling speed.

e. Cutting machine:

Precision machine cutter is able to make flat, straight cuts at high speed. A powerful suction device gathers up waste scraps after cutting, thereby making it easier for users to clean the cutter.

f. Stacking:

Automatic stacking with fixed length